After nine months of wracking my brain, and learning a few new skills—like how to cast my own alloys in a homemade forge in my backyard—this project suddenly became a full-on obsession. My wife named the banjo "Galatea," after a Greek myth in which a sculptor, in leiu of the perfect woman, decides to create her out of stone. She comes to life, and they fall in love. Seems about right. If you want to go deeper down the rabbit hole, you can check out the full build process here.

Stuff I Did:

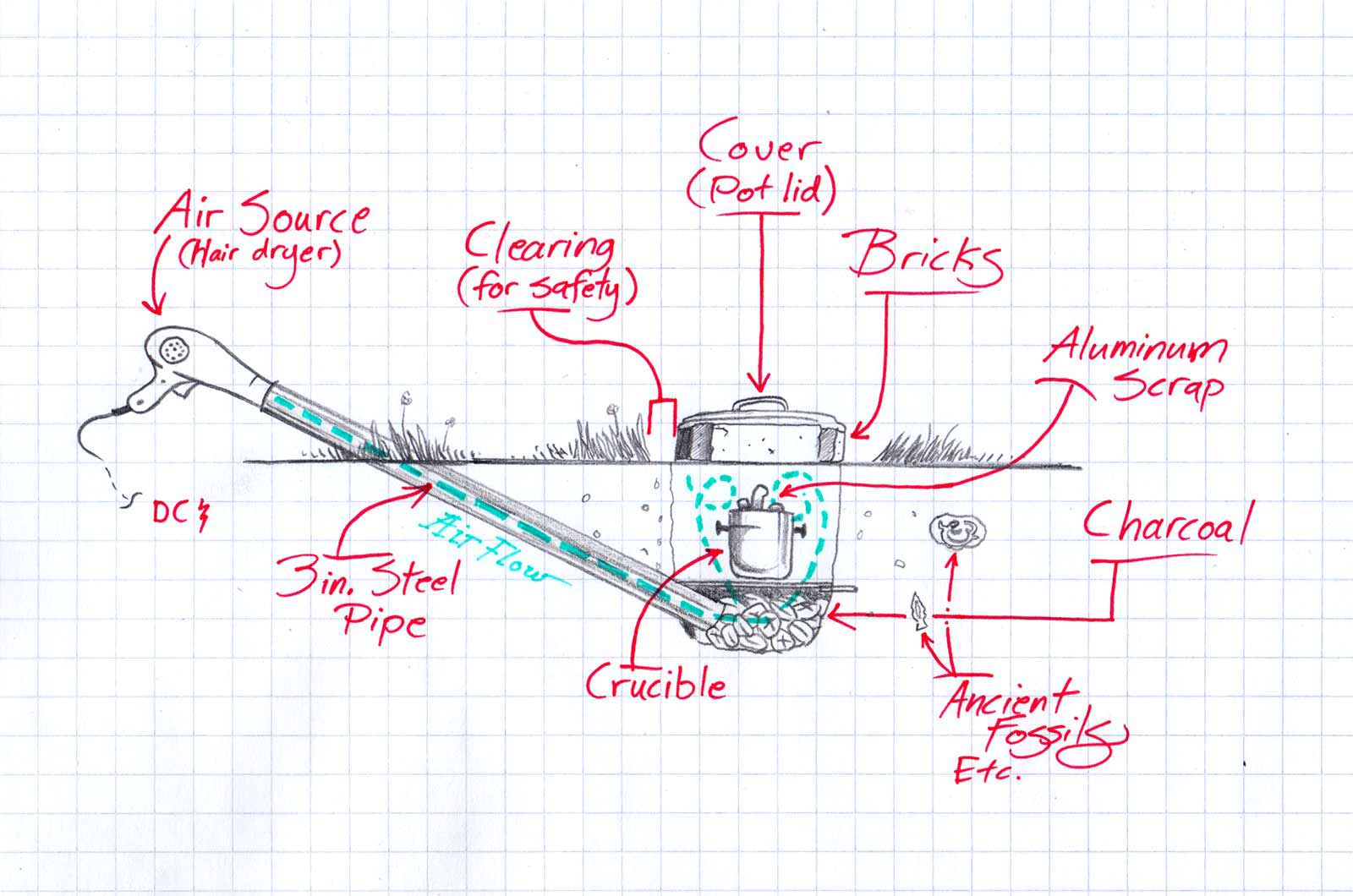

Illustration

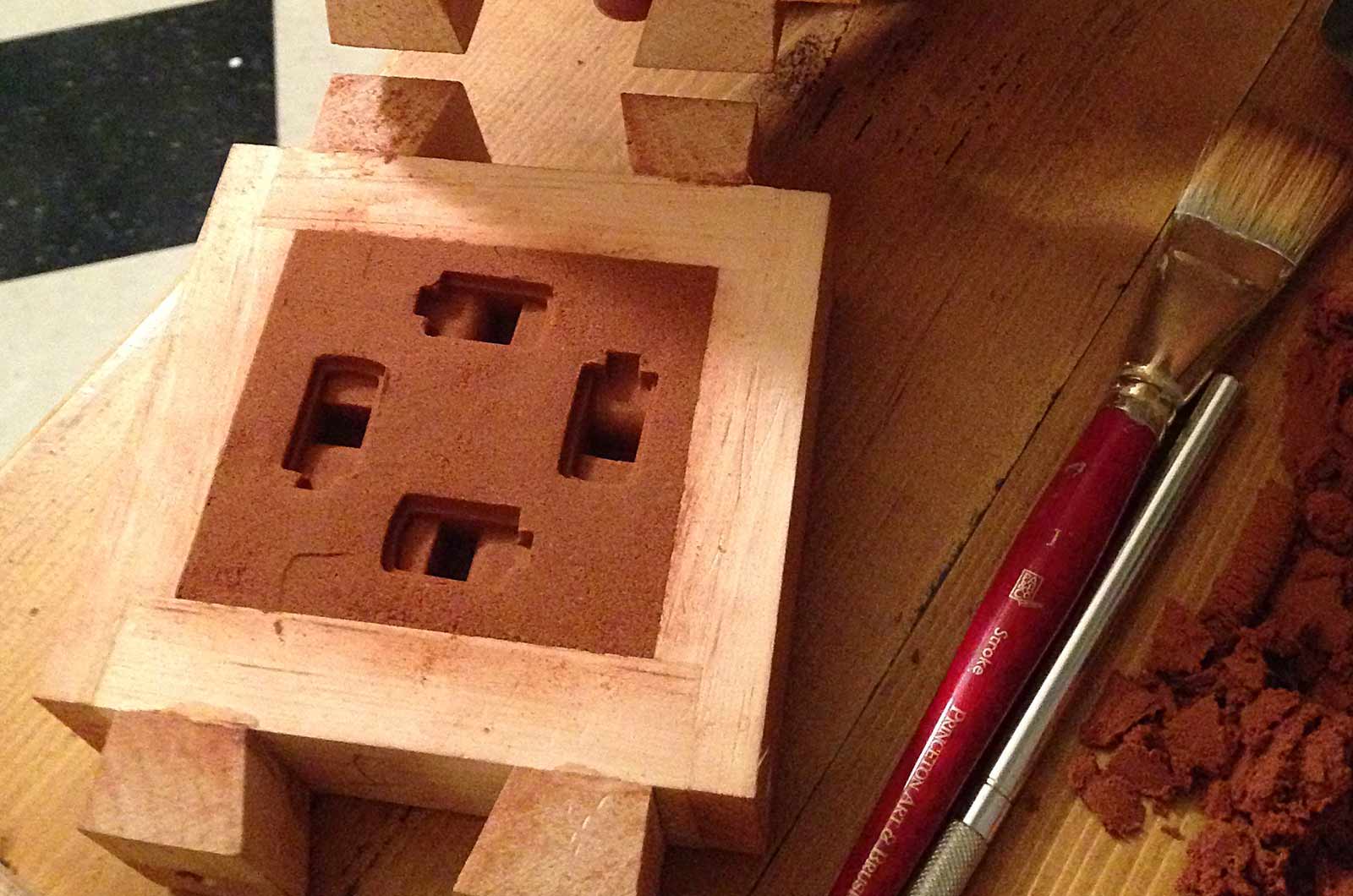

Carpentry