7 or 8 years ago, my grandfather gave me an antique Sears-mail-order “Ragtime King” banjo that had been in our family since the 1910’s. After decades of use, the fretboard was gnarled and pitted in a few common chord positions of its native G tuning. Each tuner was different, being seized from various other instruments, and requiring different screws (or in one case, physical alteration by means of a bolt cutter) to be functionally mounted onto the headstock. I repaired it somewhat shoddily (in the apparent tradition of my ancestors) to a playable state, and was hooked. I took it as a sign, and a few years later, painstakingly handcrafted a banjo over the course of 4 months that I believe to be of greater quality than an instrument I could reasonably afford. ‘Cause that’s what America is all about.

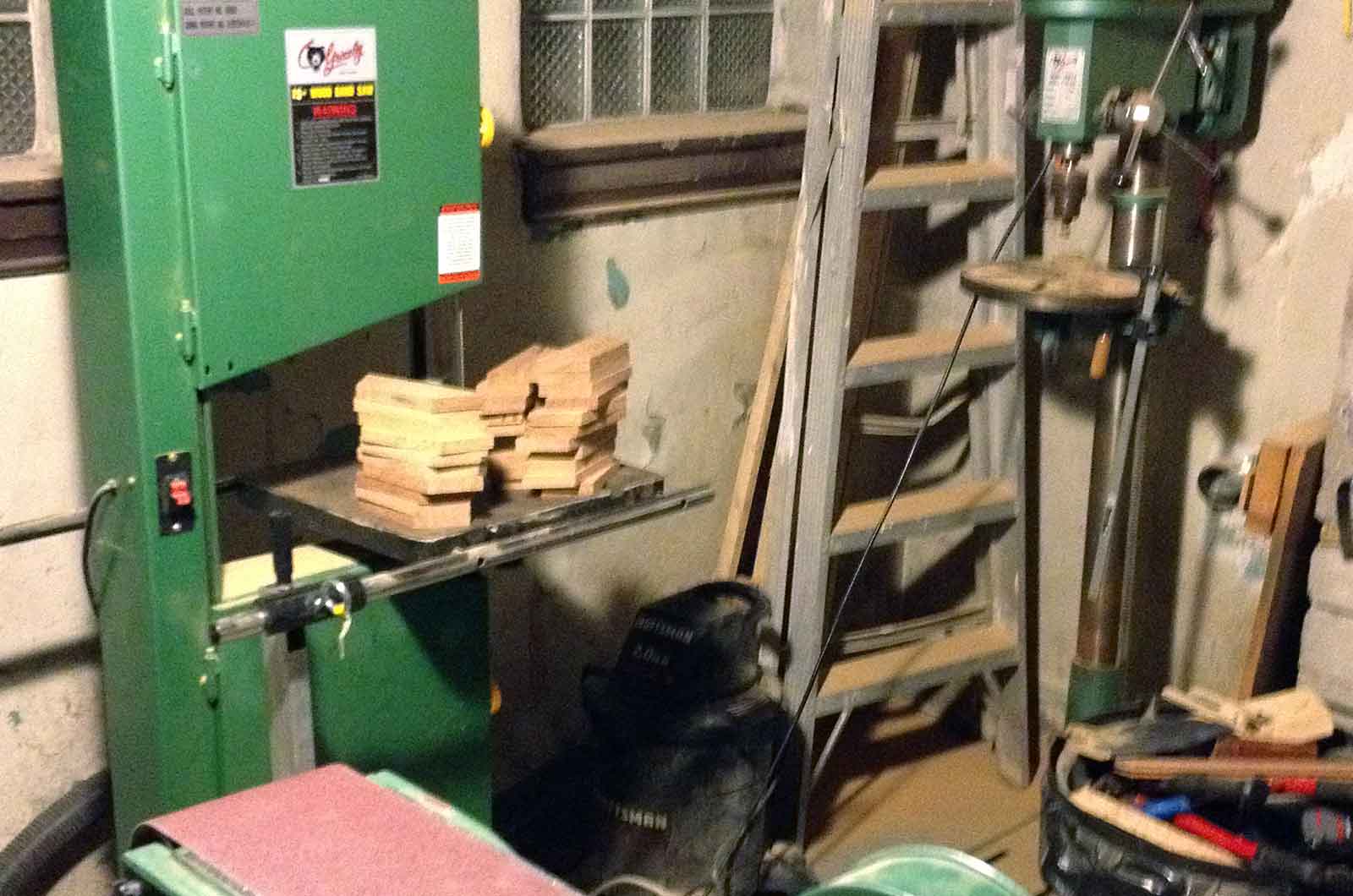

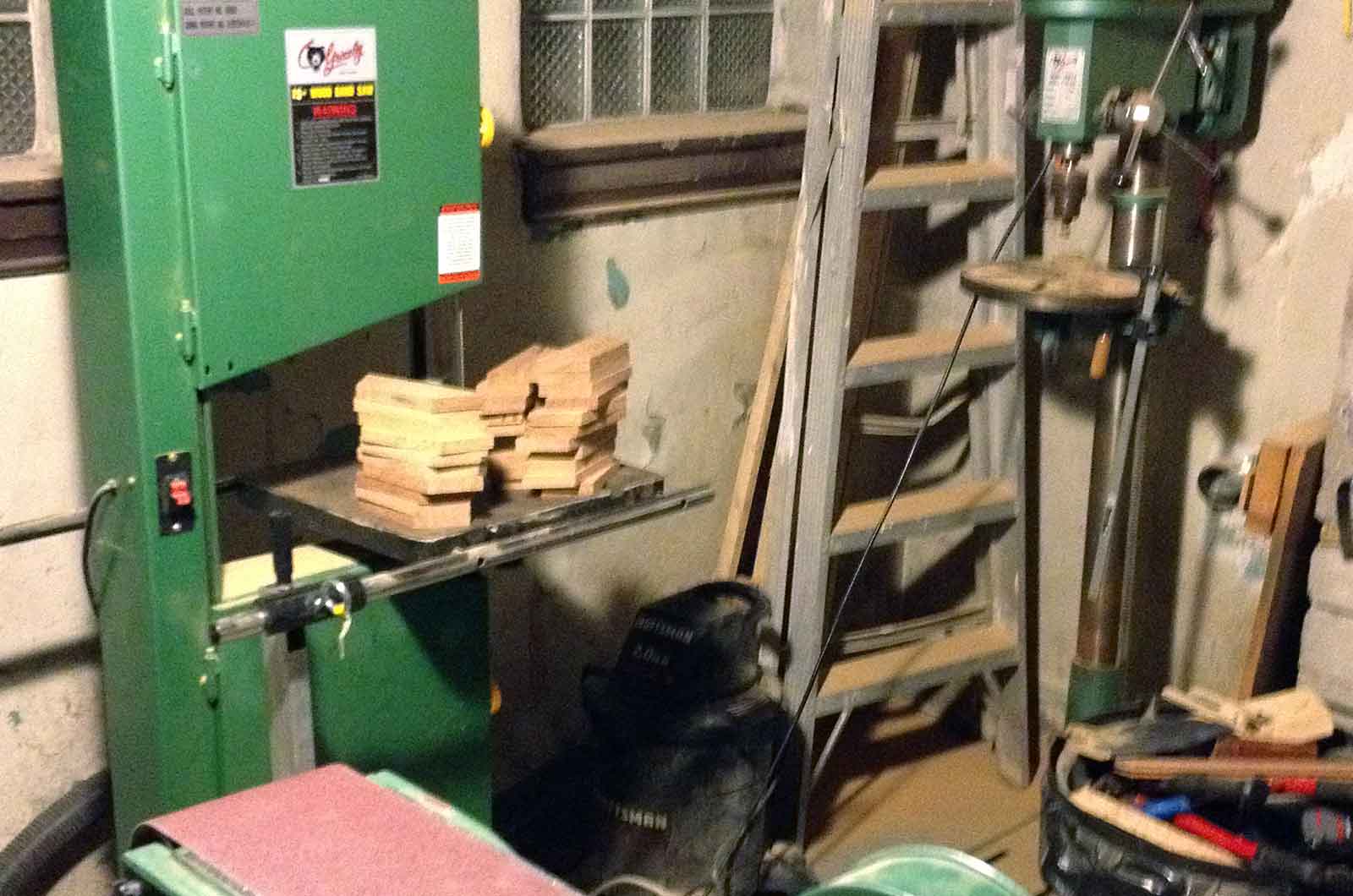

Just getting started. The pieces on the bandsaw there will become the round pot.

Probably the most complex part of the whole project: Shaping the base of the heel, where the neck joins the pot. It had to be rounded to match the face of the pot, but also at about a 3 degree angle.

I used a ton of different rasps and files (also: knives, scissors, broken pieces of glass) to shape the neck. Here I'm cutting & seating the nut.

Here's a diagram I whipped up in Illustrator to help with the layout of the hooks on the pot and the brass tension hoop (bottom), which I bent into a circle completely by hand.

Here's the completed banjo.

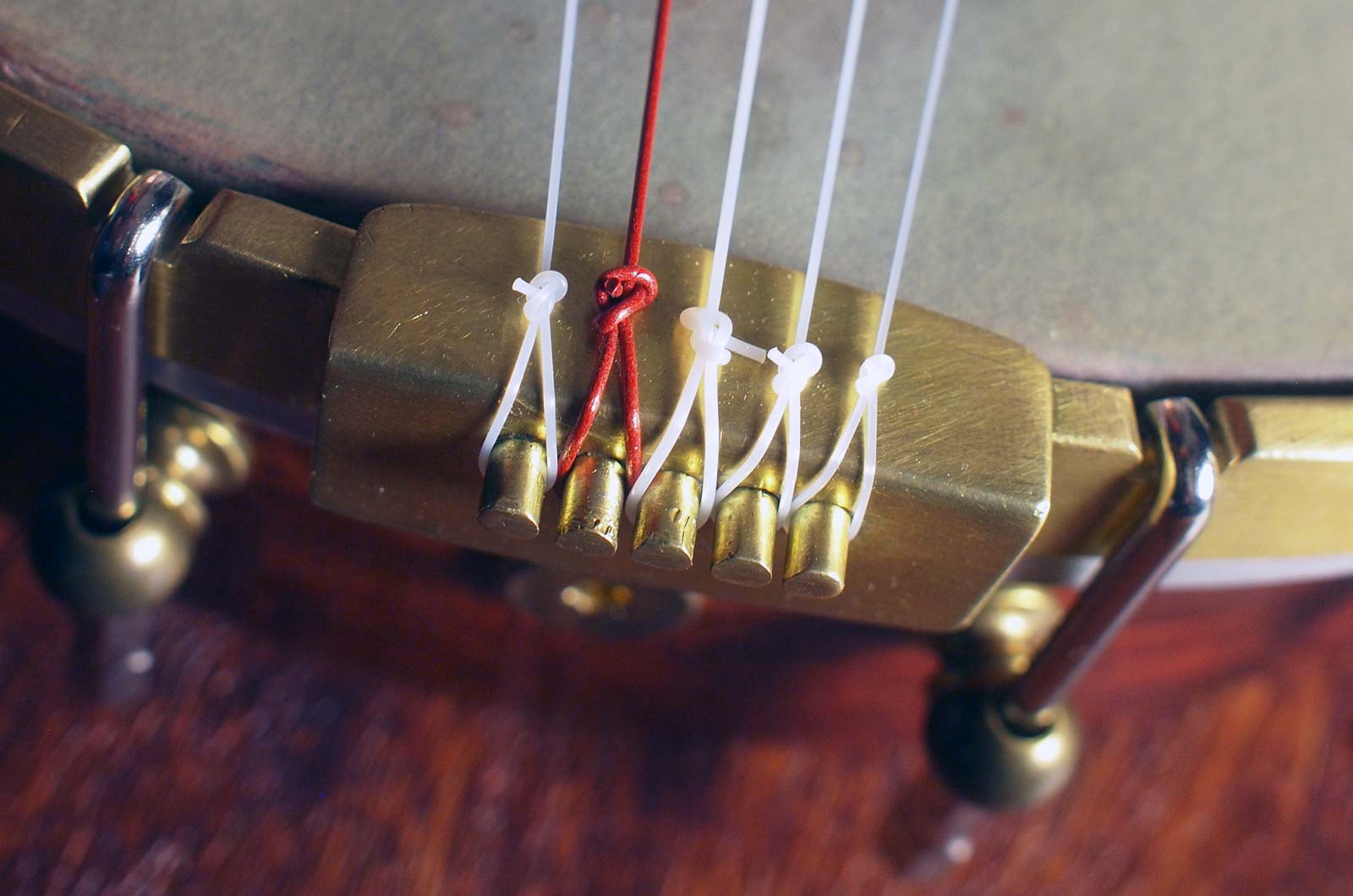

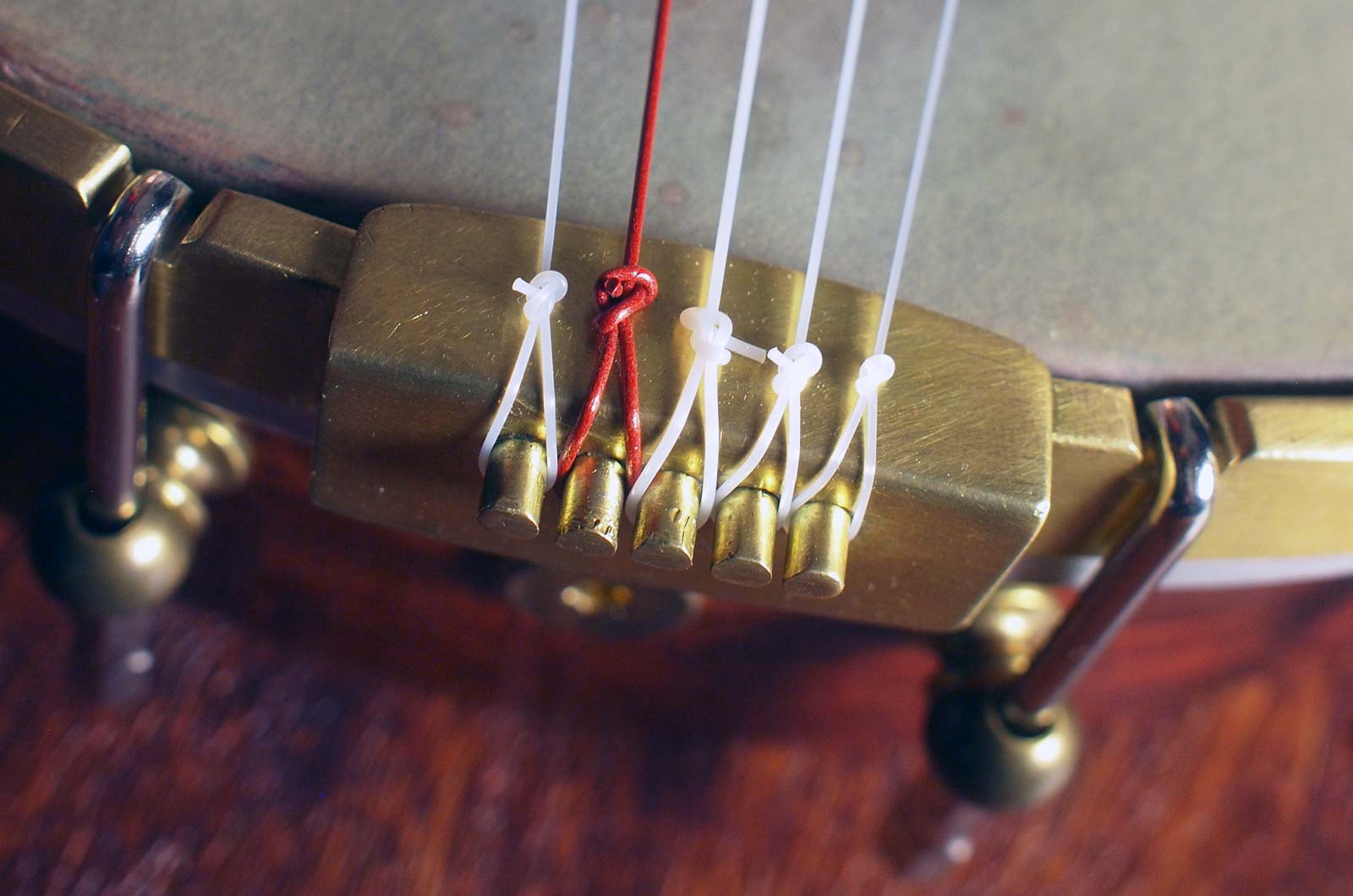

Detail of the tailpiece, which I produced from brazing rod and a brass light switch plate.

Brass failing plate, made from raw sheet brass. This feature was common on Dobson banjos from the 1800's, and I think it looks pretty badass myself.

Detail of keystone cutout on the headstock.

Detail of carving on the back of the neck at the 5th string tuning peg.

Just getting started. The pieces on the bandsaw there will become the round pot.

Probably the most complex part of the whole project: Shaping the base of the heel, where the neck joins the pot. It had to be rounded to match the face of the pot, but also at about a 3 degree angle.

I used a ton of different rasps and files (also: knives, scissors, broken pieces of glass) to shape the neck. Here I'm cutting & seating the nut.

Here's a diagram I whipped up in Illustrator to help with the layout of the hooks on the pot and the brass tension hoop (bottom), which I bent into a circle completely by hand.

Here's the completed banjo.

Detail of the tailpiece, which I produced from brazing rod and a brass light switch plate.

Brass failing plate, made from raw sheet brass. This feature was common on Dobson banjos from the 1800's, and I think it looks pretty badass myself.

Detail of keystone cutout on the headstock.

Detail of carving on the back of the neck at the 5th string tuning peg.